Skipsindustri

Offshore

Landbasert industri

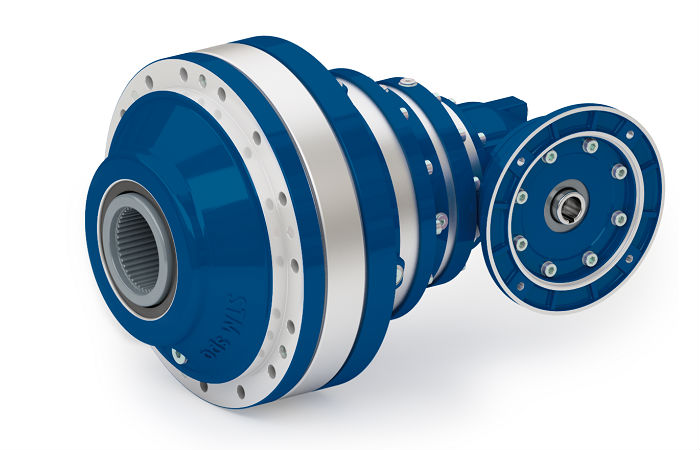

Transtech ble stiftet i 1979 i havnebyen Larvik, ca. 12 mil sør for Oslo, og leverer girsystemer og komponenter til industrien.

Enten det gjelder standardkomponenter eller spesialløsninger, gir vi våre kunder en unik mulighet til å få dekket totalbehovet fra én ansvarlig leverandør.

Transtechs mål var innledningsvis å levere løsninger til Norges raskt voksende industri. Selv om markedet var godt, ble det snart tydelig at et standard produktutvalg alene ikke var tilstrekkelig til å oppfylle kundenes behov. Vi fikk ofte modifikasjonsforespørsler fra kunder. Etter hvert ble det derfor opprettet en egen konstruksjonsavdeling, der vi kunne jobbe med egne, tilpassede designer. Det nære samarbeidet med hver enkelt kunde har vært svært vellykket.

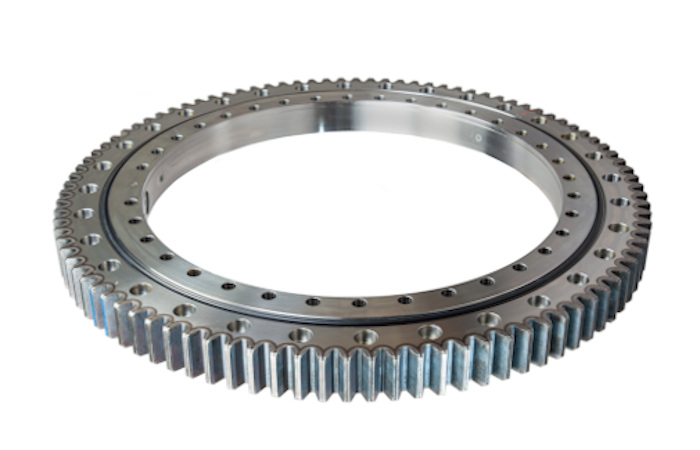

Svingkranser

Vi leverer svingkranser i et bredt utvalg størrelser og typer.

TRANSTECH AS

Transtech ble stiftet i 1979, og leverer girsystemer og komponenter til offshore og landindustrien.

ADRESSE

Øya 17

3262 Larvik, NO